That first jagged tear in your patio chair’s fabric feels like a death sentence for summer relaxation. But before you haul it to the curb, consider this: metal frames typically outlast their fabric by 15+ years, while sun-bleached or ripped upholstery fails after just 5-7 seasons. Throwing away structurally sound furniture wastes hundreds of dollars and creates unnecessary landfill waste. This guide gives you the exact methods to fix ripped lawn chairs using proven DIY techniques—whether you’re dealing with sagging sling seats, snapped vinyl straps, or punctured cushions. You’ll learn chair-specific repairs that restore tension, prevent future damage, and extend your outdoor seating’s life for another decade.

Most homeowners don’t realize ripped lawn chairs represent a $20 fix, not a $300 replacement. With the right materials and techniques, you’ll transform worn-out seating into like-new comfort using tools you likely own. We’ll cover precise measurements to avoid costly errors, budget-friendly material swaps, and professional tricks usually reserved for boat repair shops. By the end, you’ll confidently tackle any fabric failure—turning a frustrating eyesore into your favorite spot for sunset cocktails.

Repair Torn Sling Chair Fabric Permanently

Identify Your Spline-and-Rail System First

Flip your chair upside down to inspect the side rails. If you see 6-8 screws securing removable rails (not welded joints), you have the standard spline-and-rail design perfect for DIY repair. This system uses a rubber cord (spline) to lock fabric into frame channels. Measure your old spline’s thickness with drill bits—most require 3/16″ (5mm), but some need 4.2mm. Never assume; mismatched spline causes 70% of installation failures.

Gather Chair-Specific Repair Materials

Critical fabric choices:

– Phifertex marine mesh ($23/yard): UV-resistant with 10-year warranty, ideal for humid climates

– Sunbrella outdoor fabric: Premium option for pattern variety (use 10% extra for alignment)

– Shower curtain hack: Water-resistant polyester alternative under $20 at big-box stores

– Marine canvas: Heavy-duty for high-traffic areas (requires professional sewing for seams)

Must-have tools:

– Heat-resistant gloves (for handling hot vinyl straps)

– 24″ spreader bar ($10 at Harbor Freight) to maintain even tension

– Vaseline (lubricates spline insertion by 50%)

– Rust-Oleum Dark Walnut paint (matches 90% of metal frames)

Measure Without Removing Old Fabric

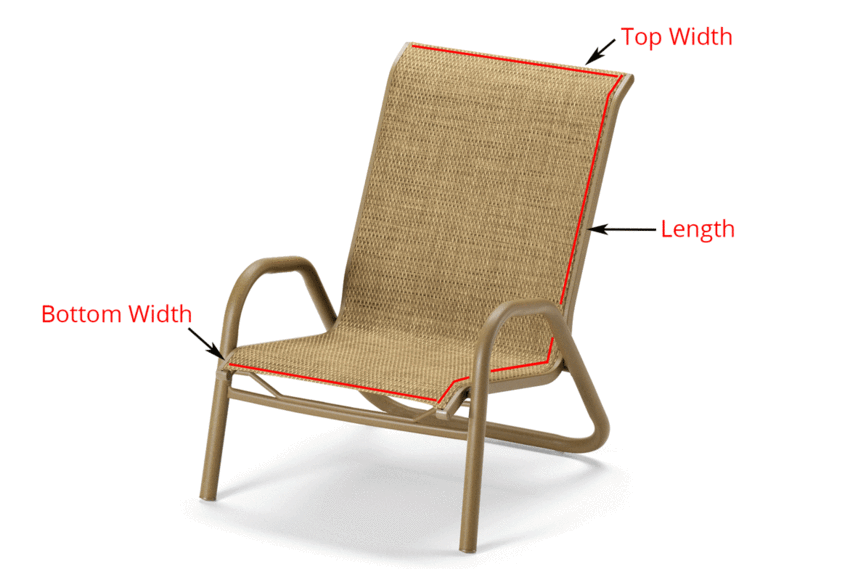

Measure center-to-center between rails at top, middle, and bottom points. Add 1/8″ to this average for the spline loop allowance—skipping this causes loose fabric. For length, measure from top rail edge to bottom rail edge plus 1/8″ safety margin. Use your old sling as a cutting template, preserving front/back orientation. If measurements vary by more than 0.5″, order custom sizing—off-the-rack fabric rarely fits perfectly.

Install New Fabric Like a Professional

Remove Old Fabric Without Frame Damage

Unscrew side rails from the chair base, then pull the fabric straight out with steady pressure. Expect resistance—the old spline creates significant friction. Completely remove the hardened spline cord before cleaning the channel with a stiff brush. Touch up paint chips with Rust-Oleum, applying two thin coats for maximum adhesion.

Cut and Insert Replacement Fabric

Lay your old sling over new material, matching grain direction. Cut 20% larger than needed—you’ll trim excess after spline insertion. Hem the sides identically to the original, leaving top/bottom edges raw for the spline channel. Pro tip: Work with one person pulling fabric taut from above while another feeds the spline from the front. Apply Vaseline to the spline cord to prevent tearing.

Secure Fabric With Perfect Tension

Keep one rail attached to the frame while feeding fabric through the channel. Use your spreader bar to maintain consistent tension as you work in 2-inch segments—not full-length sections. Bunching at corners causes 80% of failures; pause here to smooth fabric with your thumbs. Replace broken end caps with plumber’s putty rolled into 1/4″ balls—they harden invisibly once painted.

Fix Broken Vinyl Straps on Lawn Chairs

Determine Your Strap Wrap Type Instantly

Check if straps are visible after installation (single-wrap) or hidden (double-wrap). This dictates your measurement method:

– Single-wrap: Measure from hole edge, around frame, to opposite hole edge

– Double-wrap: Double that measurement for the full path

Subtract 10% from your final number—e.g., 25″ becomes 22.5″—for proper tension. Skipping this creates saggy, unusable seating.

Achieve Permanent Tension With Hot Water Method

Boil straps for 3-4 minutes until pliable. Using heat-resistant gloves and tongs, stretch each hot strap across the frame and secure with rivets. As vinyl cools, it contracts into drum-tight tension. Critical warning: Never force cold straps—they’ll snap during installation. Work in shade to prevent premature cooling.

Patch or Replace Damaged Lawn Chair Cushions

Decide Between Repair and Replacement Fast

Measure cushion width and length from hinge to hinge. If burn holes exceed quarter-size or tears penetrate both sides, replacement is cheaper than repair. Universal cushions work for 80% of chairs but verify attachment method first—some use Velcro, others snaps. For small punctures, sew decorative patches using UV-resistant Gutermann thread and a half-circle needle.

Create Budget-Friendly Cushion Alternatives

Convert shower curtains into water-resistant covers: cut to size, hem edges with outdoor-rated thread, and secure with grommets. For metal-framed chairs, replace fabric with painted aluminum strips—sand surfaces first, apply Rust-Oleum, and bolt securely. Pro tip: Store cushions indoors during rain; UV exposure causes 90% of premature failures.

Slash Repair Costs With Smart Sourcing

Buy Materials at 60% Off Retail

- Sailrite.com: Marine fabrics with 25% off first orders (use code SPRING24)

- JoAnn Fabrics: Clip 40-60% coupons during April-May sales for Sunbrella remnants

- PatioChairSupplies.com: Exact replacement straps with free sizing guides

- Fabricguru.com: Outdoor upholstery remnants under $10/yard

Time projects for early spring before peak usage season. Coordinate with neighbors—bulk strap orders from StrapKing save 30% on 10+ units. Always buy 20% extra fabric; errors happen even with perfect measurements.

Avoid These 4 Costly Lawn Chair Repair Mistakes

Measurement Errors That Guarantee Failure

- Skipping the 1/8″ spline allowance creates loose, sagging fabric

- Using rigid 3/16″ spline instead of flexible KOMORAX alternatives

- Ignoring left-right symmetry during installation (check every 6 inches)

- Forgetting end-cap backups—they break in 60% of repairs (keep plumber’s putty ready)

Cheap Materials That Shorten Lifespan

Big-box store fabrics last 1-2 seasons versus marine-grade’s 5-7 years. The 3x price difference pays for itself in avoided replacements. Store chairs upright during storms to prevent water pooling that accelerates dry rot. Inspect fabric quarterly for brittle edges—you’ll catch 80% of failures before complete tears.

How Long Does Fixing Ripped Lawn Chairs Take?

Beginner level: Pre-cut strap replacement takes 2 hours per chair with boiling water method. Intermediate level: Sling fabric replacement requires 4 hours with proper tools—allow extra time for first attempts. Advanced level: Custom cushion creation becomes a weekend project. Success signs include drum-tight fabric with zero bunching, symmetrical left/right alignment, and all hardware seated flush. When stuck, visit local shoe repair shops—they often fix chair fabric for $15 using industrial sewing machines.

Your ripped lawn chairs hold hundreds in hidden value. By applying these precise techniques, you’ll restore comfort while customizing colors to match your patio. Remember: the frame is the investment; the fabric is just maintenance. With proper care, your DIY repair will outlast store-bought replacements—proving that the smartest outdoor upgrade isn’t new furniture, but reviving what you already own.